welding belt

From a technical and structural point of view, welding belts are among power transmission belts. Other types are placed on their own pulleys and move. The round welding belt (Polycord) can be considered as one of the excellent and high quality welding belts. This type of belt is sometimes placed in a large number next to each other with small distances and can carry the products while moving

This belt has a circular cross-section, trapezoid, etc., each of which has different sizes. The material of this belt is PVC or PU, also the welded belt can be threaded or non-threaded. The method of connecting the two ends of the welded belt is thermal and the two ends of the belt are welded to each other by .heat, that is why they are called welded belts

Round welded belt (Polycord) is made of thermo plastic polyurethane and in some cases it is reinforced .with polyester thread

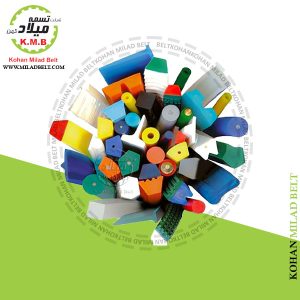

Types of welding belts

The types of belts are A-B-C-D-M-Z and their special use is in textile, printing package, machinery, glass factories, tile and ceramic industries and chemical factories

simple

threaded

Grippy

Pentagon

bridged

The temperature range of these types of belts is between -35 and 80 degrees Celsius with good resistance to flexibility and good resistance to wear and easy connection (circuit closing) is one of the good features of this belt. The diameter of round belts is from 2 to 30 mm with smooth surface and rough surface and it is available in quality European and Chinese brands

Round welding belt (Polykord – Benkord)

In general, round belts (polyurethane) or polyurethane are the standard materials that are used to produce polyurethane belts and artane rings.

Polycords can also be used to prepare these line shaft O-rings and roller-to-roller O-rings and deflect the O-rings on site inside the facility.

Round belts are a soft rubber piece used in low torque applications.

These belts are designed like an O_RING rubber ring to work in a 760 degree groove for optimal friction and bite.

Many styles of round belts are often used in tools such as electric drill motors, milling machines, and lathes.

Round welding belt (Polycord) has a thermal range between minus 35 degrees Celsius and 80 degrees Celsius.

One of the characteristics of Polykord belts is the way to connect them, which is very easy, which is done in the form of circuit closure.

Also, these belts have good flexibility against wear and tear.

Polyurd round belts can be installed well on U-shaped pulleys. The beginning and the end of the welding belt must be connected to each other by welding or metal fasteners.

The part of the money groove in which the belt is installed will have high friction and therefore belts are used when friction is not important.

The elastomeric polyurethane material used in the production of the belt creates a high wear resistance for this power transmission belt that moves on the foley. Various forms of this belt include simple, threaded, gripped, threaded, pentagonal, pentagonal, heptagonal, and finally threaded heptagonal. This type of belt is produced both in ribbed and flat form and is used depending on the needs of industries. This belt, which is also called Polykurd, has a circular cross-section, which is mainly used in sorting and separating products in industrial factories.